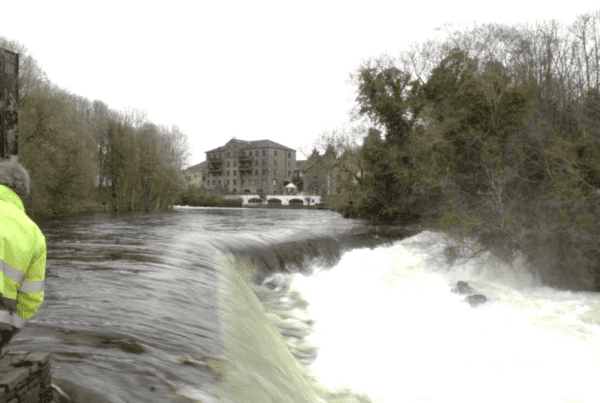

Optimise the Performance of your Hydropower Installation through Proactive, Efficient and Affordable services.

Do you feel that your Hydropower system is providing the best possible financial return and operating at its highest performance?

Many of our clients initially felt that their systems were underperforming and becoming more of a liability than an asset to them. They also felt that they didn’t really have the engineering expertise to fix the situation themselves, causing unnecessary stress, anxiety and costs!

One quick call to Hydro Maintain and a short site visit from one of our qualified engineers, answered their concerns and had them back up and running at 100% in no time.

CALL 0330 1331 555 today to find out how Hydro Maintain can relieve your hydropower management concerns and save you money too!

Who we help

Councils

Hydro Maintain provide you with:

Reliable and cost effective expertise

Stable long term O&M Agreements

Environment Agency reporting and liaison

Private Owners

You get: Peace of mind

Confidence through professional advice

Reliability & great value servicing

Environment Agency reporting and liaison

Businesses

Lower your energy costs

Improve your Hydropower asset performance

Build your businesses Governance & Social Responsibility profile

Community Projects

We know you like to do it all yourselves!

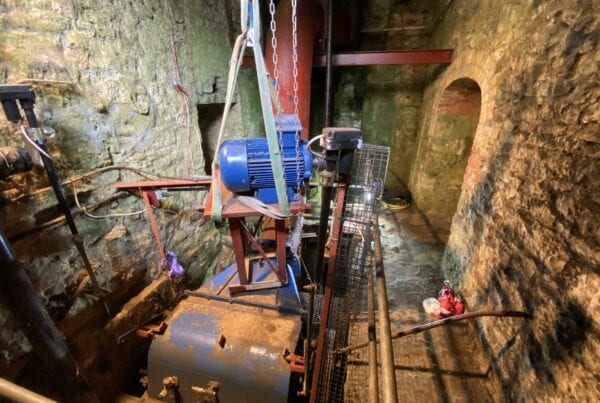

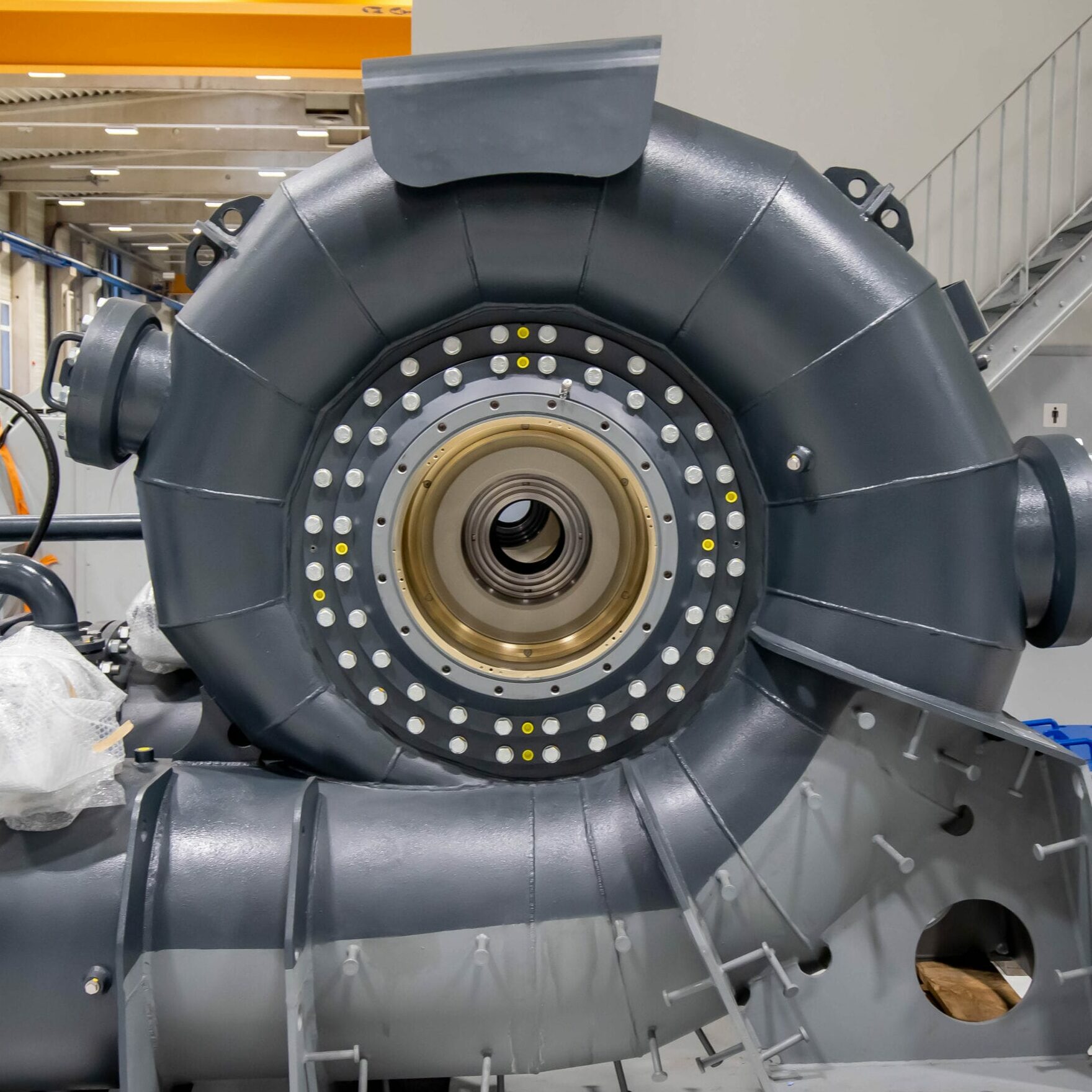

However for those bigger jobs when you really need a bit of extra support. Bearing overhaul, generator repairs, safe in-river works etc.

We're always available for free technical phone support for any uncertainties

Charities

Achieve your Sustainable Development Goals

Expert project advice and support

Keep your projects running optimally for the long term.

Investors

Reliability, Responsibility, Reporting

We can manage your hydropower investments as we do our own,

saving you costs and optimising revenues.

Let us be your responsible partner to safeguard your investor's interests

How do you prefer to work?

We manage, monitor, maintain, and operate at a completely different level.

Hydro Maintain understands your pain points, we own hydro sites ourselves.

We know how to optimise output, reduce operating expenses, and minimise management time.

Benefits for you

We can help you avoid…

- Expensive emergency callouts

- Costly breakdowns and downtime

- Expensive insurance claims

- Industry compliance issues

- Loss of income and reputation

- Environmental problems

- Time, stress, worry and money

But gain these benefits…

- Rapid and reliable response

- Protected and renewable income

- Regular system checks

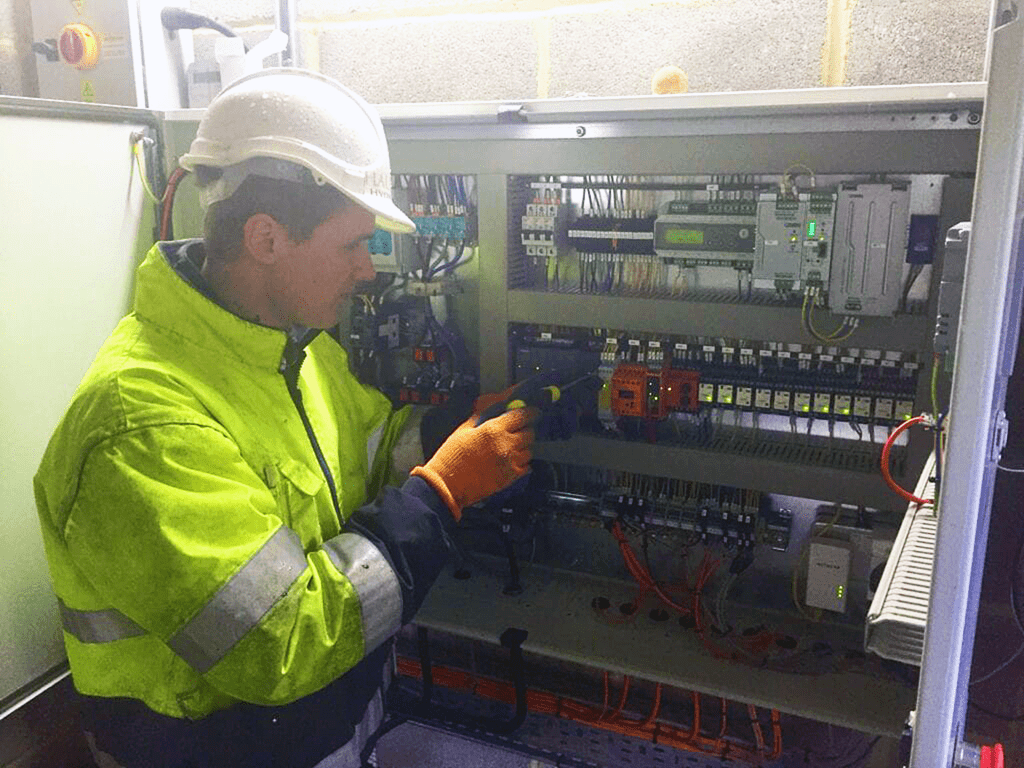

- Analysing plant performance and adjustments

- Risk assessments

- Technical monitoring

- Professional support and advice

Plus…

- Day to day admin, accounts, renewals

- Financial reporting to shareholders and legal compliance

- Support with Environment Agency, OFGEM and other regulators

- Project management and liaison

- Annual Maintenance Certificates to validate insurance

- Hallidays Hydropower O&M Guide – a bespoke, site-specific photographic guide

- Specialist equipment

- Parts sourcing

- Training of local engineers

- Expert knowledge on project sizes from 50kW to 1MWatts.

At Hydro Maintain we believe that a good maintenance company should save you time, minimise your operating costs and maximise your performance.

“We are very grateful to have had the Hydro Maintain team looking after us for the past 7 years and I would not hesitate to recommend them to anyone looking for an excellent operation, maintenance and management organisation for their Hydropower system.”

Chris, Head of Maintenance – Blenheim Palace Estate